NEED TO VACUUM SEAL POWDER?

NEED TO VACUUM SEAL LIQUID?

Start by placing your product in a vacuum pouch that has been specifically chosen for your product and application. Keep in mind that all vacuum pouches are not created equal. Almost all vacuum pouches consist of only one thin layer of nylon material to provide the air transmission barrier that is required for vacuum packaging. Other pouch materials like Mylar foil provide a much higher barrier and are much better for long term quality assurance. With a chamber unit you must make sure that the pouches dimensions are correct for your product (Fig. 1) so there will be enough space between the top of your product and the open top of the pouch thus allowing the top of the pouch to lay across the machine’s seal bar in a relaxed manor (Fig. 1). This will ensure the best quality seals on the pouch every time. A material product specialist can help you to spec in the right pouch for your product.

Once your product is inside the vacuum pouch the next step is to place it inside the chamber. The open end of the pouch should be placed over the seal bar of the unit and on top of the heating element. If you are using the optional gas flush feature on your chamber sealer then the small gas nozzles should be pointing into the opening of the pouch. Check to make sure that any part of the pouch opening does not protrude outside of the chamber. This is important because if any part of the bag is outside the chamber vacuum packaging of your product will not be achieved and the pouch may even burst.

Once the pouch with your product inside is properly placed inside the chamber then close the lid and the vacuum cycle will begin. In most cases you will want to allow the vacuum cycle to continue until the maximum vacuum that the vacuum pump in the machine can pull has been achieved. This will result is a very tight package once the entire cycle has been completed. However, if your product is of a delicate nature then a gas flush cycle (optional on most models) can be added after the vacuum cycle. Gas flushing allows the pressure inside your pouch to be increased so the pouch will not collapse on your product at the end of the cycle but allows the residual oxygen level to remain as low as possible unlike a package that was only subject to a partial vacuum. It is often recommended that only a light vacuum should be applied to delicate products however, that will allow much more oxygen to remain in your package once it is sealed thus robbing you of the benefit of vacuum packaging. Adding an inert gas to increase the pressure inside your package provides far superior results.

Inside the chamber during the vacuum cycle air rushes out of the chamber at a greater rate than it escapes from inside your package. This allows the pressure inside the package to be a little higher than in the surrounding chamber. This is normal and the should diminish as the vacuum cycle continues. However, make sure the end of your pouch does not pull away from the seal bar. You can watch this through the clear acrylic lid on some models or need to check the end results on other models without clear lids. Many machines also offer a simple pouch holding mechanism (Fig. 4) to help make sure the end of the pouch stays properly placed over the seal bar.

The end of the pouch needs to be heat sealed completly so that no air will be able to enter the pouch at the end of the cycle when the chamber cavity is opened exposing the content. The sealing of the pouch is accomplished in most chambers with a simple time-based impulse seal system. However, if your pouch material has a very narrow seal temperature window or your package must be validated then you may require an optional temperature controlled or even a validatable seal system. Be sure to talk over your specific product and application needs with an IMPAK vacuum sealing equipment specialist.

Once your package is sealed then a valve in your chamber sealer opens and allows outside air to go back into the chamber cavity and for the lid on your machine to open. If only a vacuum cycle and a seal cycle were completed the pouch will be compressed very tightly around your product. If a gas flush was added, then depending on what volume of gas was introduced to the inside of your pouch then the disposition of the pouch may be anywhere from firm to very loose around your product. However, in all cases the residual oxygen inside your package will be very low.

Chamber vacuum sealers are the most flexible type of vacuum sealers as they allow for the vacuum sealing of both liquids and solids as well as allowing for extremely low residual oxygen even when working with delicate products.

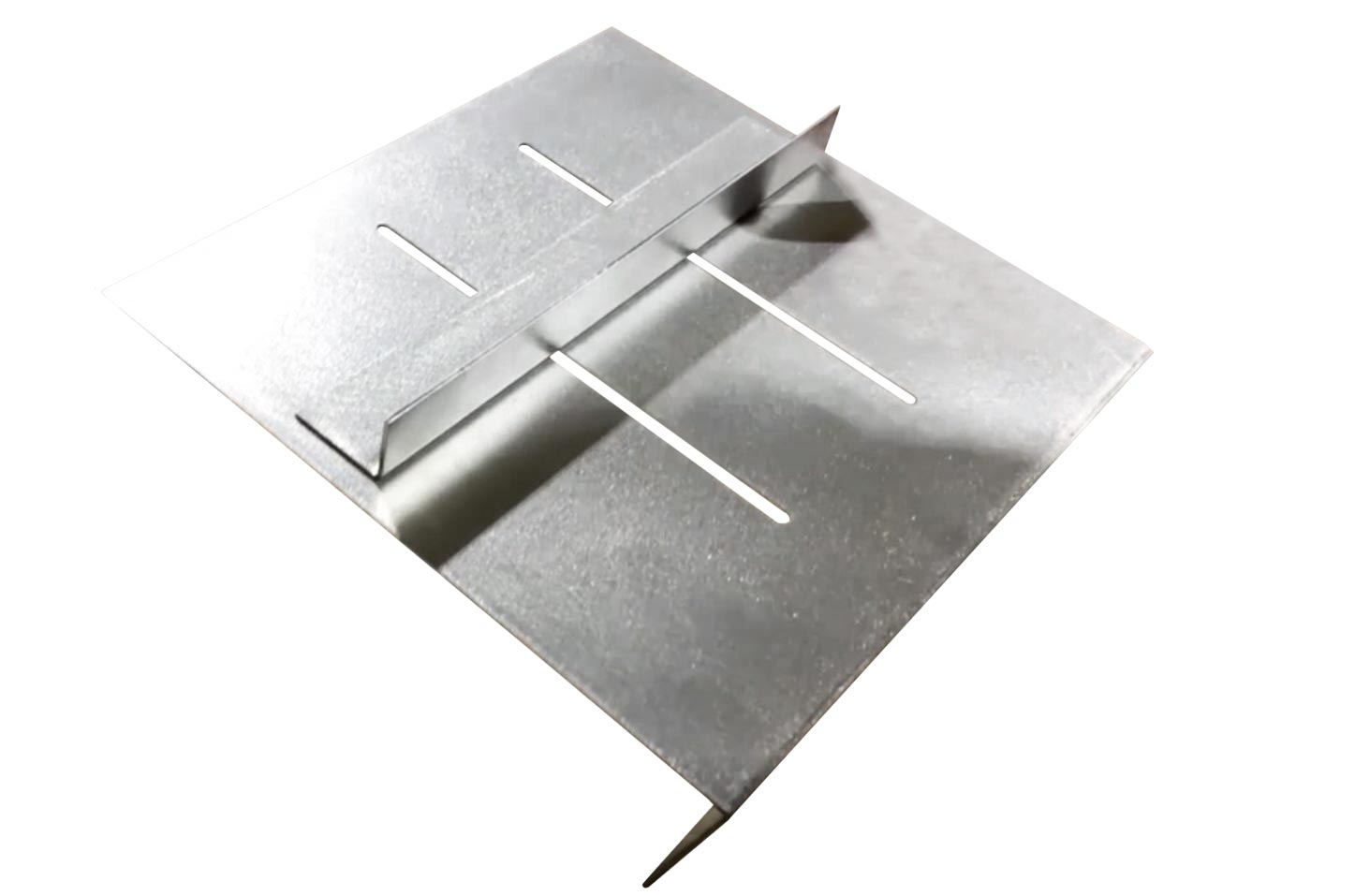

Yes, powders can be vacuum sealed. The best method for vacuum sealing powders is to use a chamber vacuum sealer with our optional slant tray.

(Need to vacuum seal a liquid? The chamber style vacuum sealer is the best sealer to use for vacuuming liquids. It doesn’t require excessive pre-vacuum steps. The slant tray simplifies the sealing process for liquids.)

Putting powders (and other products) in a chamber vacuum sealer is quick, easy, and doesn’t require much extra preparation.

The Best Method for Vacuum Sealing Powder – Use a Vacuum Chamber Sealer with optional slant tray.

A chamber vacuum sealer works best as the pressure inside the vacuum bag reduces at the same rate as the internal pressure in the chamber. Because of this the powder stays inside the bag instead of being sucked out* of the opening. Also, the chamber vacuum sealer requires no wait time between seals and there is no mess.

*(Make sure the contents inside the bag is cooled below 100°F before using the vacuum chamber to seal a liquid. As the pressure in the chamber reduces, so does the boiling point of the liquid which can cause the liquid to boil out of the bag.)

See video below of sealing process with Gramatech Chamber Sealer with optional slanted tray

A hermetic seal on flexible packaging can be achieved with any of our sealing machines, this quick guide will help you choose the unit that will work best for your production needs.

Not every Industrial Vacuum Sealer applies to every application. There are different models and types of Vacuum Sealers available, and each one of those sealers has different features that can affect the way a production line works.

We design and manufacture custom sealing equipment to meet the unique needs of our customers. In addition to new machinery we even retrofit our customers’ existing equipment, regardless of the brand.