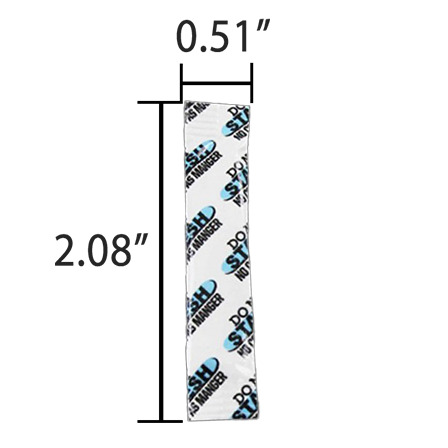

Compression-molded desiccants are specialized moisture-absorbing materials that undergo a unique manufacturing process known as compression molding. In this method, the desiccant material is subjected to high pressure and heat, resulting in a dense and uniform structure. This compression molding technique enhances the desiccant's effectiveness in removing moisture from its surroundings. These desiccants are designed to be compact, making them ideal for applications where space efficiency is crucial. The compression molding process allows for the creation of custom shapes and sizes to suit specific needs, providing a versatile solution for moisture control in various industries such as electronics, pharmaceuticals, and food packaging. The resulting compression-molded desiccants exhibit excellent performance in maintaining the integrity and quality of sensitive products by preventing moisture-related damage. Speak to our team to discuss custom options. orders@sorbentsystems.com

Custom Options - Whether you need printed or unprinted MiniPouches, we can supply pouches to your specific dimensions. We are known for producing some of the smallest pouches on the market. We also offer a wide range of print capabilities including matte/gloss finishes, frosted films, and much more. Custom Print Form