Starting Price: $5,840.00

Available Seal Lengths:20.0" and 25.0"

Standard Features:

"IMPAK’s iS2(Intelligent Sealing System) is a platform that utilizes an advanced Siemens PLC, Siemens HMI, and proprietary pneumatic and electrical components to produce heat/vacuum seal solutions. The ports and features it provides that make the calibration easy and efficient. Over the years, IMPAK has invested resources in developing features and technologies to advance its heat and vacuum sealers."

- Johnathan Brown, PME Services, Inc.

iS2 20.0" Sealer

Part Number: iS2-20

In Stock in Australia

In Stock in Australia

iS2 25.0" Sealer

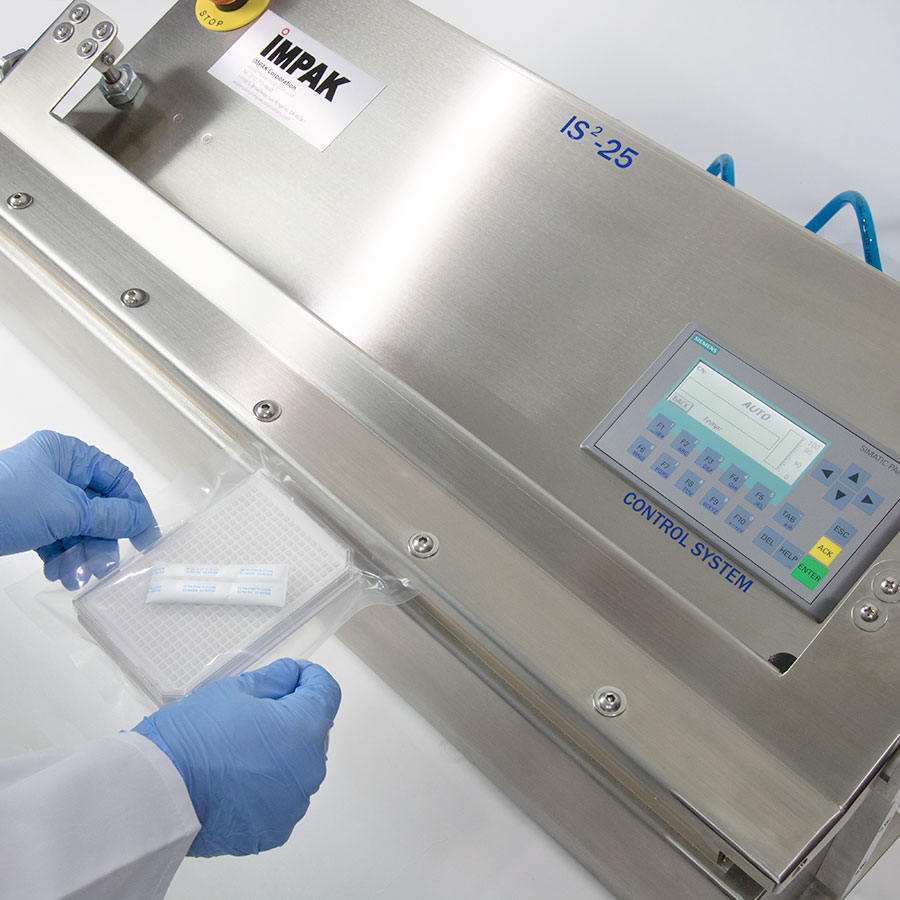

Part Number: iS2-25IMPAK Corporation introduces the new iS2 Series Medical Tabletop Sealers which offer unprecedented accuracy and feature an upgraded controller which produces clean validatable seals every time, temperature control within one degree, accurate sealing time with readings every millisecond.

The iS2 Sealers are an improvement to our MPD Series Machines, which we still offer our full support on. Learn more about the superior iS2 Series below.

About the iS2 Validatable Medical Pouch Sealers

These thermal impulse sealers offer unparalleled consistency and are ideal for all tabletop medical pouch-sealing applications where budget or space is a paramount concern. They answer the need for accurate readings every time by providing you the ability to precisely control the time, temperature and pressure to accurately seal the material, repeatedly. This makes these pouch sealer machines ideal for clean room settings as required by the discerning needs of the medical packaging industry. Ideal for a range of materials such as thermoplastics and laminated foils.

Each medical pouch sealer is pneumatically operated and is available in 15, 20 or 25-inch seal lengths. A digital temperature controller allows you to program the temperature settings required to provide you with an airtight/watertight seal and the release temperature for your cool cycle. A variable timer ensures precise control over the amount of time heat is applied to your package.

Each medical heat sealer is validatable and calibratable. The quality construction provides years of trouble free operation.

Standard safety features guarantee the utmost protection for your operator. The stainless steel finish ensures clean room compatibility and options such as the selection of different size heating elements and water or air cooling bar are available.

All medical pouch sealing units are complete with a one-year warranty, detailed operating instructions and spare parts kit.

Additional options include: 220V, expedited order, 3rd party calibration. Learn more

Optional Safety Guard for iS2-20 and iS2-25

| Sealing Width | 0.25" (0.5" available) |

| Temperature Range | 100°F - 475°F |

| Voltage / Hz. | 110V / 60HZ standard (220V option available) |

| Power | (10 - 15 amp) |

| Machine size | 15": L = 18.5" x W = 12" x H = 8.5" 20": L = 24.5" x W = 12" x H = 8.5" 25": L = 29.5" x W = 12" x H = 8.5" |

| Weight | 15": 45 lbs 20": 49 lbs 25": 52 lbs |

iS2-20 Spare Parts Kit

Part Number: MPXSPPT20

$255.50

iS2-25 Spare Parts Kit

Part Number: MPXSPPT25

$286.48

iS2-20 Spare Parts Kit

Part Number: MPXSPPT20D

$305.50

iS2-25 Spare Parts Kit

Part Number: MPXSPPT25D

$296.48

A hermetic seal on flexible packaging can be achieved with any of our sealing machines, this quick guide will help you choose the unit that will work best for your production needs.

Not every Industrial Vacuum Sealer applies to every application. There are different models and types of Vacuum Sealers available, and each one of those sealers has different features that can affect the way a production line works.

We design and manufacture custom sealing equipment to meet the unique needs of our customers. In addition to new machinery we even retrofit our customers’ existing equipment, regardless of the brand.