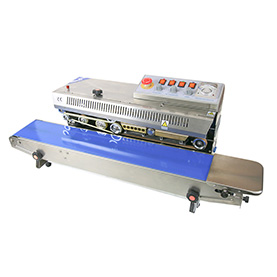

Band Sealers

Band Sealers may be the most efficient, versatile semi-automatic sealing machines on the market today. Also known as "belt sealers", the Impak RapidSealer™ utilizes a conveyor belt to maximize sealing capabilities. The extra seal embossing ability integral with these continuous rapid sealer machines make them the perfect solution for companies needing a means to include lot and serial numbers, company names and brand names on their products.

Need Vacuum and/or gas flush capabilities? Try the:

VakRapid® Series

| RSH1525SSDC | PHR1525 | RSV1525SSDC | PVR1525 | RSH1575SSDC | RSV1575SSDC | RS2225 | RSV1370 | |

|---|---|---|---|---|---|---|---|---|

| Digital Temperature Controller | check | check | check | check | check | check | check | check |

| Right and Left Side Feed Available | check | check | check | check | check | check | check | check |

| Stainless Steel Finish | check | check | check | check | check | check | check | check |

| Vacuum and/or Gas Flush Capability | check | - | check | - | check | check | check | check |

| Emboss (E), Dry Ink (DI) or Inkjet (IJ) Printer Available | E | IJ | E | IJ | DI | DI | DI | - |

Benefits of a Rapid Sealer™

label Semi-Automatic Bag Sealing

Typically seals faster than the operator can supply bags into the feed.

label InkJet, Print & Emboss Options

Most units have emboss or print options for dates, lot codes and more. Our PrintRapid™ series comes with an InjkJet cartride system built in.

label Robust & Durable Construction

Referred to as “workhorses,” these machines run long days with trouble-free operation.

labelEasy Maintenance

Consumable parts such as bands and Teflon are easily replaced and installed.

label Horizontal or Vertical

Versatile configuration options for flat and stand-up pouches.

label Powder-Coated or Stainless-Steel

Powder-coated models are an easy to clean, whereas stainless-steel meet food handling requirements.

Interested in Learning More?

A hermetic seal on flexible packaging can be achieved with any of our sealing machines, this quick guide will help you choose the unit that will work best for your production needs.

Not every Industrial Vacuum Sealer applies to every application. There are different models and types of Vacuum Sealers available, and each one of those sealers has different features that can affect the way a production line works.

We design and manufacture custom sealing equipment to meet the unique needs of our customers. In addition to new machinery we even retrofit our customers’ existing equipment, regardless of the brand.