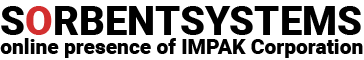

Tabletop Vacuum Sealers

Tabletop vacuum sealers are made for light to heavy production vacuum packaging and come with available options ranging from all-electric or pneumatic units, powder-coated or stainless-steel, clean room compatible, gas-flush capable and more. IMPAK offers a wide selection; from small vacuum sealers for sous vide applications at home, all the way up to industrial grade vacuum sealers for the medical industry, food packaging plants, electronics, and industrial products packaging.

Compared with a heavy equipment purchase such as freestanding sealers, the tabletop units can be an economic and highly flexible option that can be moved within a production line or even to another facility. We often see customers purchase several tabletop units in lieu of larger equipment, thus reducing downtime as well as investment costs.

IMPAK offers completely custom units, or a wide selection of “stock” items below.

| HIPPO | EVS Models | PVS Models | Gramatech Models | |

|---|---|---|---|---|

| Operation | All-electric | All-electric | Pneumatic | Electric & Pneumatic Units |

| E-Stop | - | - | check | check Select Models |

| 220V Available | - | check | check | check |

| Stainless Steel | - | check | check | check Select Models |

| iS2 Upgrade Available | - | - | - | check Select Models |

| Bi-Active Seal | - | check Upgrade Available | check Upgrade Available | check Upgrade Available |

| Gas-Flush | - | check | check | check Select Models |

| Seal Length | 12.5" | 14", 18", 23" | 18", 23", 31", 36" | Many sizes, 16" - 61" |

| USA Made | - | - | - | check |

Benefits of a Tabletop Vacuum Sealer

labelSmall Footprint

Tabletop vacuum sealers require less space than large, freestanding units.

labelPortable / Flexible

Can be moved within a production line or to a different facility without heavy crating or forklift.

labelRange of Options

Choose from many different models at varying price-points and capabilities. Speak with a specialist for help.

labelEconomic, Low Investment Cost

No need to buy more machine than necessary. Save by creating an effective line, not excess machine.

labelCustomizable Units

Many models come with a range of options to choose from, and IMPAK can build completely custom machines.

labelTechnical Support Team

IMPAK’s technicians can help from the product selection stage, well into the lifecycle of your machine.

Helpful Links

Choosing a Vacuum Sealer - learn more

Choosing the Right Sealer for Your Setting - learn more

Calibration Services - learn more

What Does "Validatable" Mean? - learn more

The Validatable iS2 Upgrade - learn more

Custom Sealing Equipment Options - learn more

info Why are Fuji Impulse Sealers being replaced with IMPAK’s EVS units?

A Matter of Convenience & Control

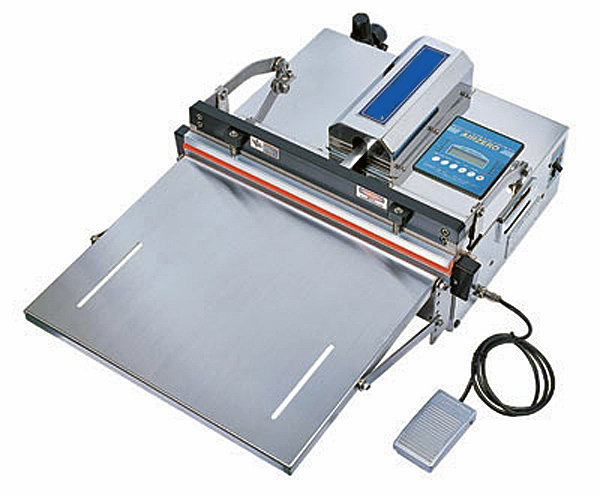

Fuji Impulse Sealers by Fuji-Sotex of Japan are known for their quality and reliability. So why are companies with working Fuji units replacing them with our EVS units?

It comes down to convenience and control.

IMPAK’s EVS units not only allow operators to digitally program 5 different seal recipes, they also allow a keypad lockout that prevents unwanted changes to the recipes. This gives companies peace of mind that their packages are consistent, time after time.

In addition to this added level of control, the EVS units are favored for their convenient operation. Instead Fuji’s manual nozzle, the EVS units have an automatic nozzle that retracts at the end of the vacuum cycle. This means the EVS can be operated using only the foot switch.

To top it off, the EVS units have a stainless steel frame, which is not only easier to clean, it is also a requirement for many industries. See them here.

Interested in learning more? Speak with our specialists.

Previously Stocked Sealers

We no longer sell, but still service the following items. If you are looking to purchase a new unit of any of the following items, contact our team as we may still be able to provide.

We Rent Vacuum Sealers

Interested in Learning More?

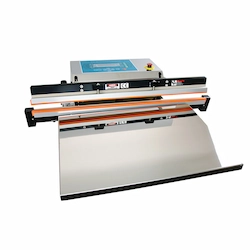

Need precise control of time, temperature and pressure? Upgrade to the Intelligent Sealing System (iS2). Digital control over time, temperature and pressure, plus a touch screen interface, recipe storage and more.

A hermetic seal on flexible packaging can be achieved with any of our sealing machines, this quick guide will help you choose the unit that will work best for your production needs.

Not every Industrial Vacuum Sealer applies to every application. There are different models and types of Vacuum Sealers available, and each one of those sealers has different features that can affect the way a production line works.