The EVS is one of the most customizable sealers available. With the option for 3 gas flushes and 4 vacuums, a range of vacuum styles can be performed from light and extreme vacuums to pillow packs.

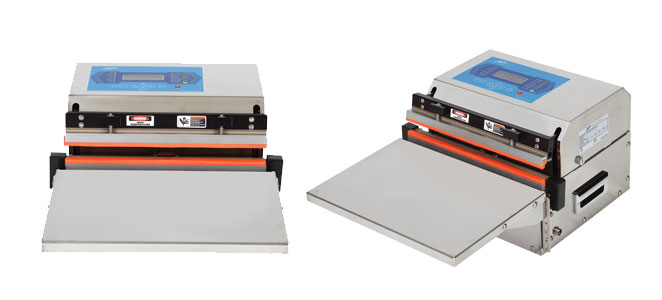

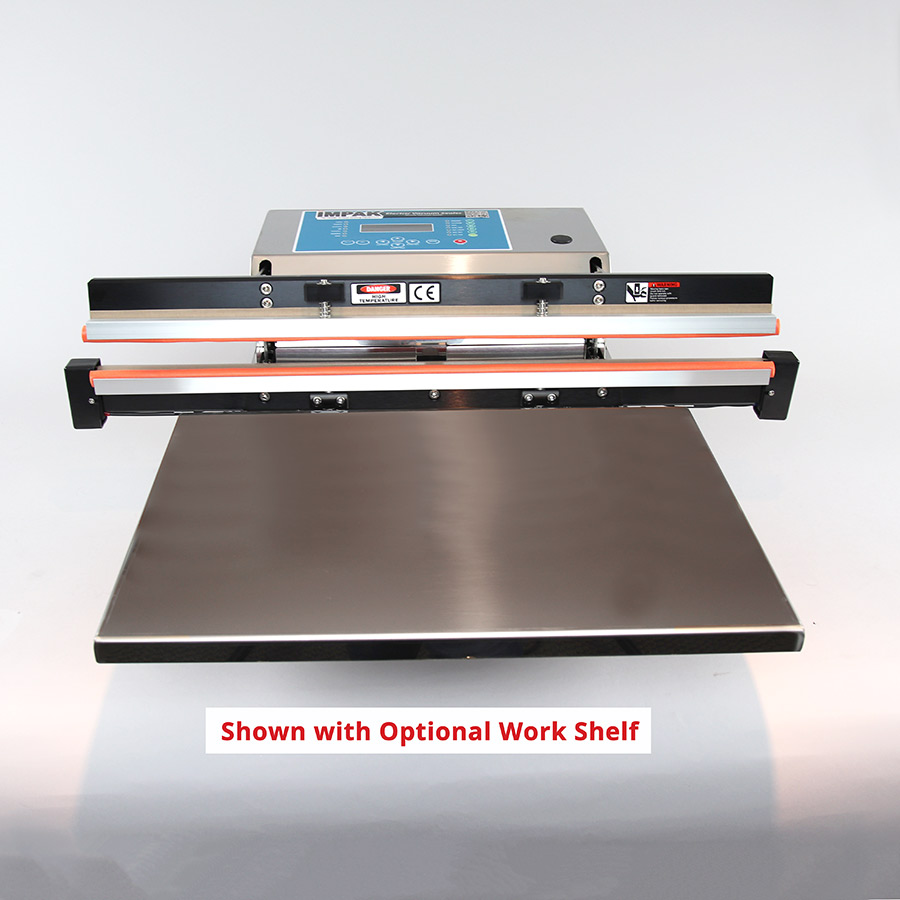

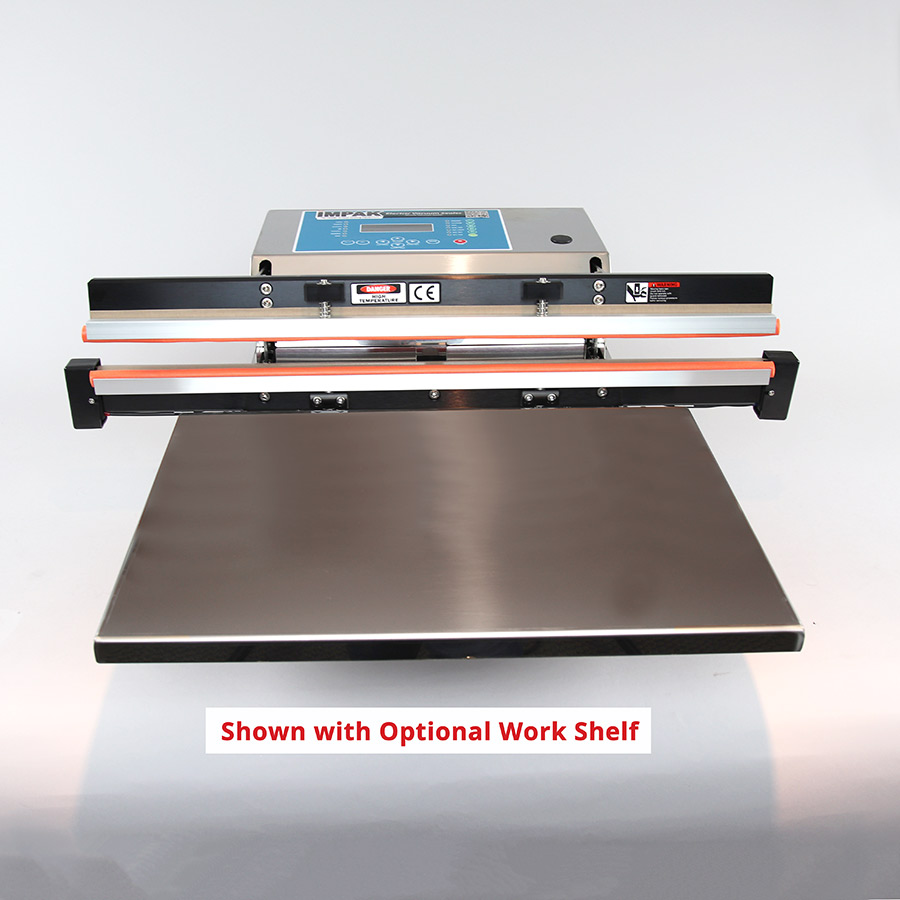

These nozzle type all-electric industrial vacuum sealers are outstanding units for medical and clean room use. Unlike air driven pneumatic sealing machines, IMPAK’s electric sealers have no need for an air compressor source. Since the sealers do not require an air compressor unit, these motor-driven vacuum sealers will work more quietly than other pneumatic-driven vacuum sealers on the market. Our EVS series sealers, available in 14”, 18” and 24" wide units (350mm, 450mm, and 600mm respectively), come STANDARD with upper and lower dual elements assuring hermetically sealed bags. High quality stainless steel materials and quality plating finishes combined with the highest industry quality components deliver a production-ready industrial grade machine that will be reliable and long lasting in any high production work environment. With a 19” x 14” footprint, these compact units can fit into extremely small places. Even with the highly recommended and eminently useful stainless steel tray the total footprint on the unit is 19” x 26” on the larger 18” wide seal bar unit.

Must Recieve Order before 1:30pm EST

These units are CE compliant, with documentation available.

“Compared to the Amerivac units I have had over the years it feels like I never change the elements and in fact I am not even sure where the spare parts kit that I purchased with this fantastic little machine is located.”

“Better quality, stainless steel, and built & shipped to me within 4 days of ordering.”

“If I was running IMPAK those machines would be priced higher than their competitor." - San Jose, CA Operations Manager

Uline is a packaging distribution company that is well known for quality products, extremely rapid service and product availability.

The machine pictured above replaced 4 Uline units at a major East Coast Bio-Medical Facility. They were experiencing unusually excessive maintenance and repair issues. With our EVS series they saw instant improvement, the cycle time was faster as well as the quality of the seal was better. They considered the replacement a well worth upgrade and a valuable investment.

Someday perhaps this machine will be private labeled for the Uline Corporation by IMPAK.

Specifications

Specifications

Specifications

Specifications

Specifications

Specifications

The EVS is one of the most customizable sealers available. With the option for 3 gas flushes and 4 vacuums; a range of vacuum styles can be performed from light and extreme vacuums to pillow packs.

These nozzle type all-electric industrial vacuum sealers are outstanding units for medical and clean room use. Unlike air driven pneumatic sealing machines, IMPAK’s electric sealers have no need for an air compressor source. Since the sealers do not require an air compressor unit, these motor driven vacuum sealers will work more quietly than other pneumatic driven vacuum sealers on the market. Our EVS series sealers, available in 14”, 18” and 24" wide units (350mm, 450mm and 600mm respectively), come STANDARD with upper and lower dual elements assuring hermetically sealed bags. High quality stainless steel material and quality plating finishes combined with the highest industry quality components deliver a production ready industrial grade machine that will be reliable and long lasting in any high production work environment. With a 19” x 14” footprint, these compact units can fit into extremely small places even with the highly recommended and eminently useful stainless steel tray the total footprint on the unit is 19” x 26” on the larger 18” wide seal bar unit.

These units are CE compliant, with documentation available.

| Sealing Lengths | 13.8", 17.7", 23.6", 31.5" |

| Seal Width | 0.2" Standard |

| Pump | Electric Motor Pump | Airflow Rate | 25 liter, 40 liter |

| Electrical | 110v, 50/60 Hz |

IMPAK produces custom printed pouches and packaging with an emphasis on materials with distinctive barrier properties to protect products from the adverse effects of moisture, oxygen, light and more. Learn about our unique custom capabilities.

High barrier bags are used to preserve and protect products. When paired with an oxygen absorber or desiccant, products enjoy even greater shelf-life and stability. However, selecting the appropriate package is not always as straight forward as it seems.

Not every Industrial Vacuum Sealer applies to every application. There are different models and types of Vacuum Sealers available, and each one of those sealers has different features that can affect the way a production line works.