WHO WE ARE...IMPAK is known for its production of flexible packaging and sorbents that help our customers achieve controlled atmosphere packaging solutions. We are also extremely proud of our world-class machinery group. The machinery group is an established leader in providing solutions to the most challenging demands in the market for thermal impulse and constant heat sealers. When it comes to heat sealing equipment that requires vacuum technology and capability, IMPAK equipment beats the competition, because we KNOW their products.

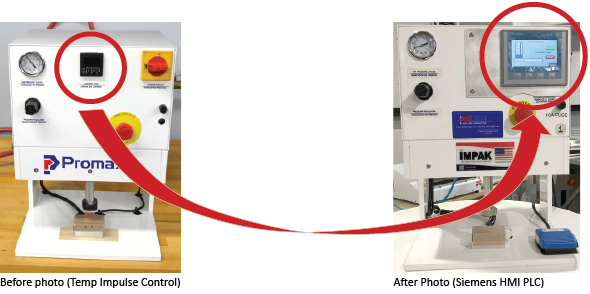

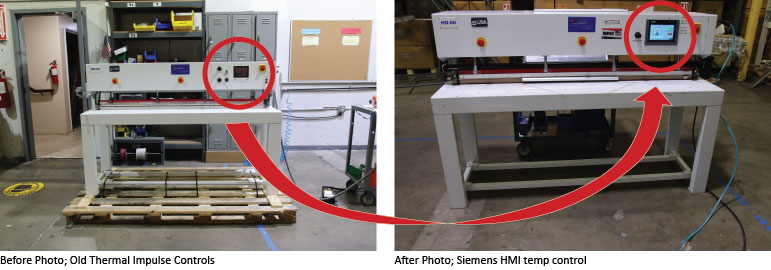

IMPAK has expanded our Customer Service Operation to include ASSESSMENT and overhaul of most Impulse Heat Sealers made by virtually any manufacturer WORLDWIDE including Aline, Accu-seal, Vertrod, PAC, Promax, Fuji and more. We can retrofit your existing equipment with the latest technology platform which runs on a Siemens HMI platform.

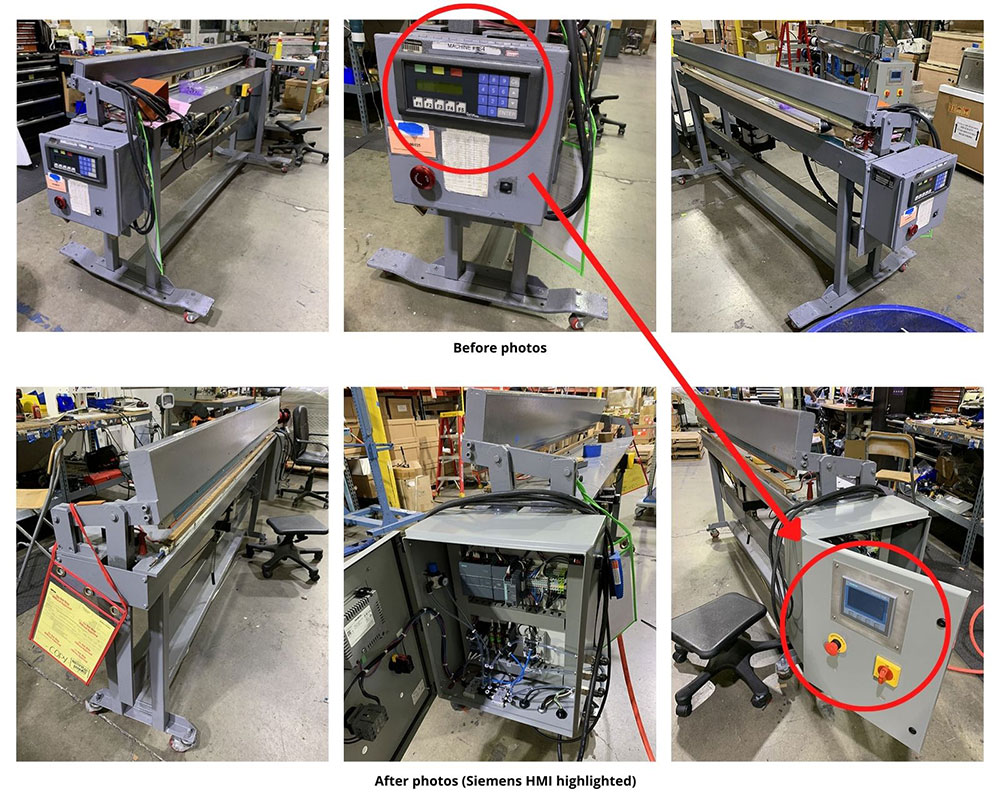

EXAMPLE 1: Remanufacture and Upgrade 60 and 72 inch Vertrod** Heat Sealers (Summer 2022)

Need: Robust, temperature-controlled heat sealing for variable thicknesses of substrates

Challenge: CML* has 6 Vertrod sealers that operated very reliably and consistently over the years. As a result of age, electronic parts and programs were scarce, and in many cases, no longer available.

Solution: IMPAK offered two solutions:

Because the sealers originally manufactured by Vertrod had served them so well, and because of their confidence in IMPAK’s ability to design an appropriate solution, CML* selected our remanufacturing alternative.

Results: The advanced electronics and pneumatics provided for remarkably improved and accurate heat sealing, increased throughput, and drastically reduced cost of ownership, mainly from increased life of wearable (aka ‘consumable’) materials. These materials include PTFE (aka Teflon) covers, heat bands, insulator tape, and silicon compression sponge which, as a nature of impulse heating, wear over time. Temperature-controlled (as opposed to timed) heat sealing saves both materials and labor, from downtime and the time it takes to change out the materials.

| Throughput: |  |

Increased 3X |

| Seal strength / integrity: |  |

Increased 2X |

| Seal temp accuracy: |  |

Increased to 99.94% |

| Cost of ownership (MRO): |  |

Decreased 50% |

* We refer to our client as CML for “Composite Materials Leader” instead of their company name because of our commitment to their privacy and the terms of our NDA.

** Having invented the thermal heat sealing process more than 70 years ago (it is 2022 as of this writing), it’s no surprise Vertrod has sealers still in use today at industries ranging from packaging to composite material manufacturers. Originally located in Brooklyn NY, Vertrod ceased operations many years ago. Some of the sealers they made are still in operation; their rugged construction and long term reliability has allowed them to function when properly maintained by the user.

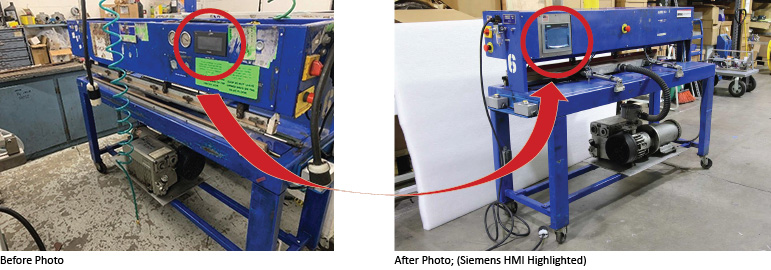

Challenge: PPL, a world leader in the production of pet products, had a quantity of 10 individual, 60 inch long, Heavy Duty, (HD) Large Frame Industrial Grade impulse heat sealers with high speed vacuum function and custom designed vacuum nozzle (originally produced by Aline Corporation from 2005 to 2014.) PPL’s challenge started as a result of explosive demand for their products caused by the Covid-19 pandemic. In conjunction with this sudden rise in demand for their products, they realized their existing sealers had degraded to the point that meeting their multi-shift operation schedule was jeopardized. To resolve PPL’s issue, IMPAK’s proposals to convert to a Siemens PLC based Temperature Control System was accepted by the customer.

Solution: PPL chose to refurbish and upgrade existing sealers with the IMPAK iS2 Temperature Control System. It not only significantly increased throughput, it dramatically decreased consumable spare part expenditures by 78.6% (heater bands and PTFE Covers) and downtime and also, realized labor costs to change consumable spare parts.

The video below shows the refurbished Aline HD-60 LFIG Heavy Duty Impulse Sealer in action:

*We refer to them as PPL, for “Pet Products Leader,” instead of their company name because of our commitment to their privacy and the terms of our NDA. (Spring-Summer 2021) Note: Although Aline went bankrupt in 2012, IMPAK Corporation’s Machinery Group is committed to supporting and manufacturing all of the equipment previously produced by Aline.

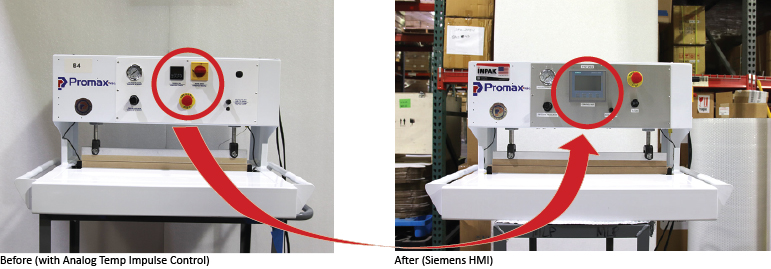

Challenge: Updating old LFIG Sealer with new control panel and safety features

Solution: Replace control panel with Siemen's system, and added safety features like lockout and extra 10ft cable separated stop botton.

Challenge: Sealing performance degraded and replacement parts became scarce for their existing heat sealers.

Solution: Overhaul and upgrade to IMPAK’s iS2 Temperature Control System with Siemens HMI and expand seal length to 26.5 inches (673 mm.) (winter 2019)

Challenge: Sealing performance degraded and replacement parts became scarce for their existing heat sealers.

Solution: Overhaul and upgrade to IMPAK’s iS2 Temperature Control System with Siemens HMI. (winter 2019)

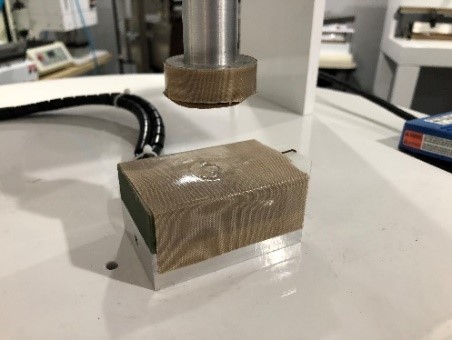

One Inch Diameter Heating Block and Seal

Heavy Duty Circular Sealer Video

Challenge: Their two Aline, 48-inch Heavy Duty (HD-48) Large Frame Industrial Grade Impulse Heat Sealers were no longer functioning and replacement parts were no longer available.

Solution: Due to their frequency of use, the client decided to overhaul and upgrade their existing sealers and chose IMPAK to perform the upgrade to Siemens based PLC iS2 Temperature Control System.

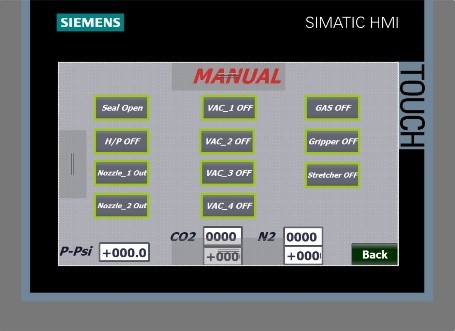

Retrofitted Explosion Proof sealer for Lockheed Martin with IMPAK’s Intelligent Seal System, (iS2) Explosion Proof Foot pedal and other mechanical and electrical modifications.

Aline Horizontal Explosion Proof Impulse Heat Sealer

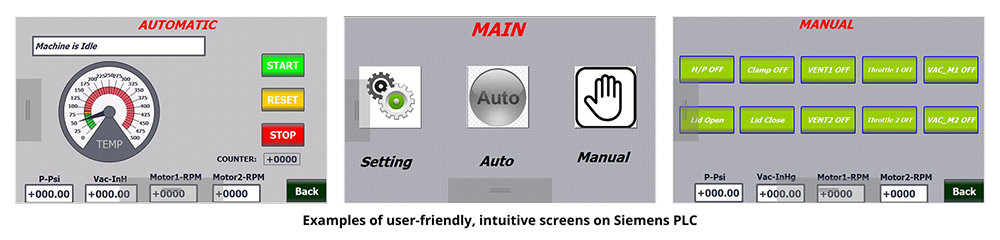

Example of Siemens HMI screen

Do you have a 20+ year old unit that needs to work in an explosion-proof environment – send us your machine and we’ll retrofit it with our iS² intelligent sealing system utilizing the most modern Siemens PLC and HMI – just ask Lockheed Martin.(See example screen shot below.)

It doesn’t matter who built it originally or when – from the defunct A-line Corporation to the nonexistent Thermoseal equipment manufacturer or the well-respected Accu-Seal Corporation of San Diego, CA. For example, we have converted a 48” Accu-Seal bar sealer from a one sided into two sided heat when the company would not do it even though the end-user was located 7.6 miles from the Accu-seal facility.

Accu-Seal dual heat band after upgrade

We started with 17 units and were able to make 11 of them work again. Here is a picture of the 3 that are left.

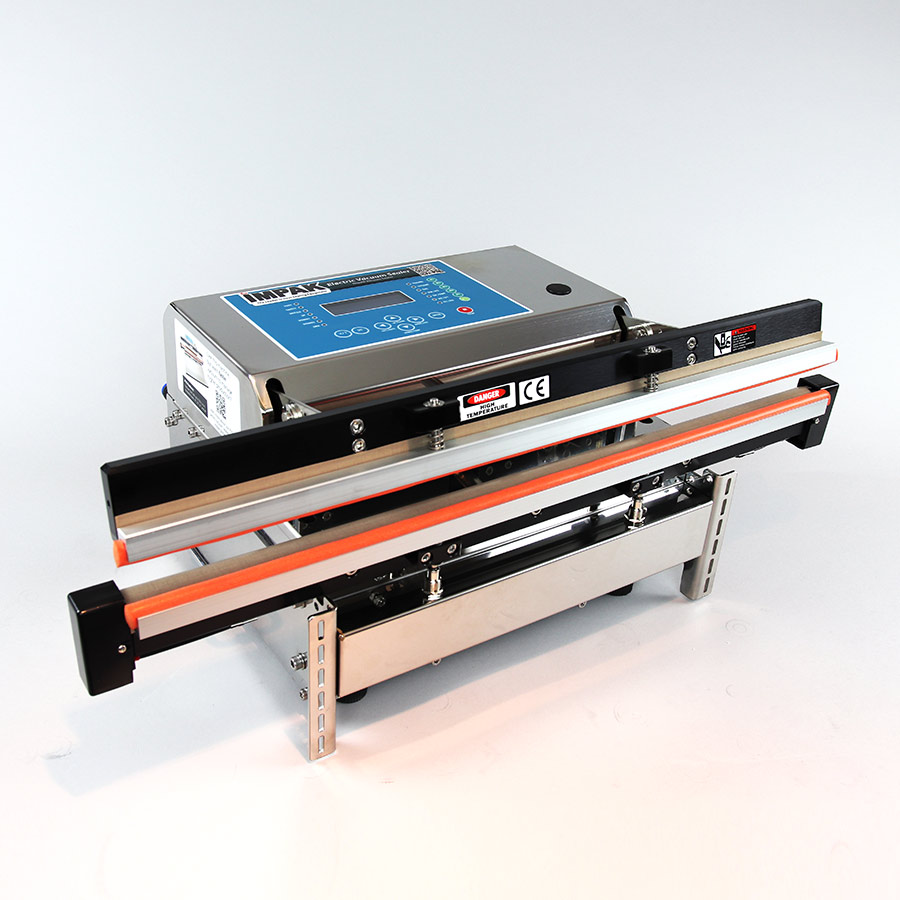

Fuji sealers (left) replaced with IMPAK stainless steel, All Electric Impulse, Vacuum Sealer (right)

Purchase IMPAK exclusive all electric, stainless steel vacuum sealer here

How about a chamber unit with precise temperature and pressure controls large enough to hold a 72” X 84” object? Or a 3/8” seal on a 120” wide bar unit with a flying knife that is sealing 6 to 8 mil film, from a roll, and cutting it at the same time? WE HAVE DONE IT. See detials here:

Evolution of Innovation in Capability and Scalability

Heavy Duty(HD) 60" Impulse Sealer with Pneumatic Cutter and Intelligent Sealing System

Heavy Duty(HD) 60" Impulse Sealer with Pneumatic Cutter and Intelligent Sealing System Demo