Vacuum sealer bags are made from specialized materials with the structural integrity to withstand the rigors of vacuum packaging. Vacuum seal pouches are widely used in kitchens for food storage and cooking, for packaging foods to prevent oxidation, in industries that require a low oxygen environment for their product, and by those who need to compress items to save space.

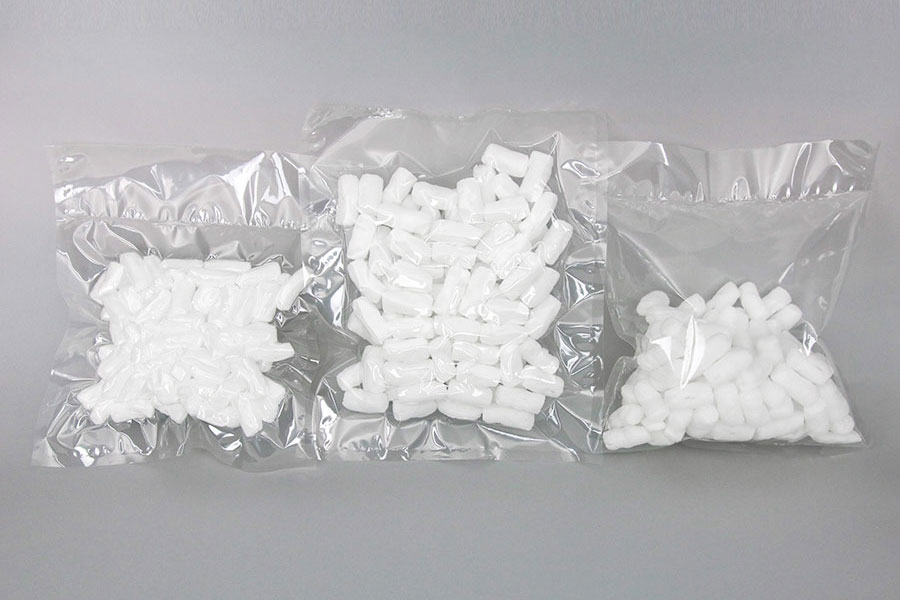

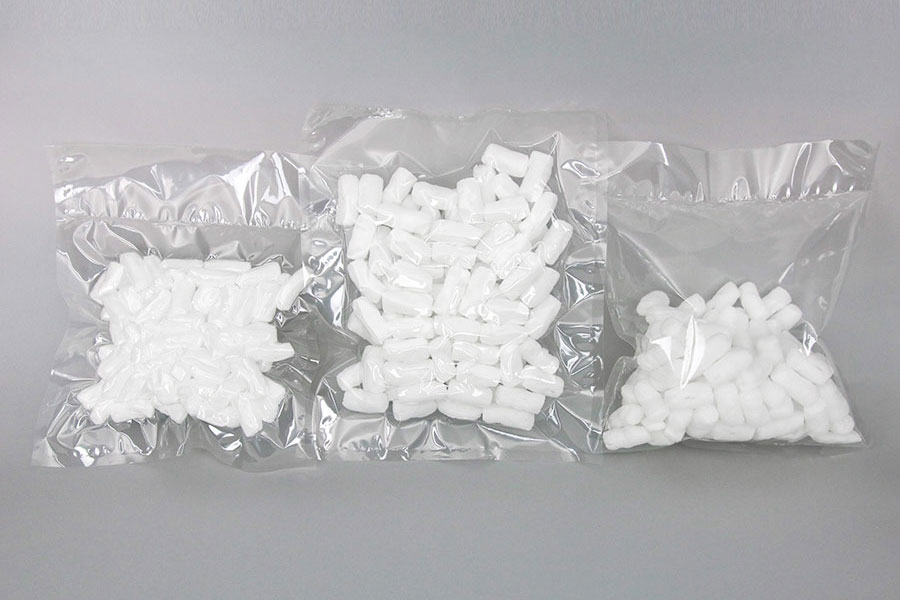

Vacuum seal bags come in two styles: textured (or channeled) pouches for use with home vacuum sealers such as FoodSaver® and CounterMate™, and non-textured (or smooth) pouches for use with most industrial sealers. PLEASE NOTE: These styles are not cross compatable. Smooth surface vacuum bags will not work with external clamp home sealers. IMPAK offers both styles, including vacuum bags with zippers. Vacuum packaging bags from many brands are often as thin as 3.0mils, but for a better barrier, IMPAK provides thickness options of 4.0mils, 5.0mils, and more.

Our vacuum seal bags are food grade, FDA compliant and BPA free. They are ideal for sous vide and cryovac cooking techniques.

We ordered a large volume of Shield N Seal products to help with national coverage. We now have these high-demand products IN STOCK for immediate shipping. Click here to see these bags or contact us directly for information on all the Shield N Seal products we offer.

Shield N Seal vacuum sealer bags are sturdy food-grade textured surface (channel style) bags that seal in moisture and odor while protecting contents from contaminants and freezer burn. These 5 mil heavy duty vacuum seal pouches provide an impenetrable barrier when properly sealed, making them perfect for sous vide cooking, freezing, vacuum sealing processed hops and hemp, and preserving freeze-dried produce, fish, and meat. These bags are compatible with popular home vacuum sealer brands like Foodsaver®, CounterMate®, Anova, Vevor, Nesco®, Geryon, Seal-A-Meal®, VacMaster®, Avid Armor, LEM MaxVac, FoodShell, Deni Freshlock, Cabela’s®, Minipack, Kenmore®, Weston, Magic Vac, Black & Decker®, and more. Click for Shield N Seal Bags

Custom Pouches: Many pouches are produced to customer specifications with a choice of sizes, colors, printed and unprinted. For more information provide the size, application, and quantity required to: inquiries@sorbentsystems.com

IMPAK produces custom printed pouches and packaging with an emphasis on materials with distinctive barrier properties to protect products from the adverse effects of moisture, oxygen, light and more. Learn about our unique custom capabilities.

High barrier bags are used to preserve and protect products. When paired with an oxygen absorber or desiccant, products enjoy even greater shelf-life and stability. However, selecting the appropriate package is not always as straight forward as it seems.

Not every Industrial Vacuum Sealer applies to every application. There are different models and types of Vacuum Sealers available, and each one of those sealers has different features that can affect the way a production line works.