What Is Mylar?

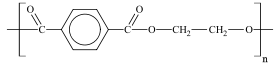

Mylar®, also known as BoPET (Biaxially-oriented polyethylene terephthalate), is a polyester film made from stretched polyethylene terephthalate (PET) and is used for its high tensile strength, chemical and dimensional stability, transparency, reflectivity, gas and aroma barrier properties, and electrical insulation.

BoPET film was developed in the mid-1950s, originally by DuPont, Imperial Chemical Industries (ICI), and Hoechst. The term "Mylar" is presently a registered trademark of the DuPont Teijin Corporation.

Because polyester film is less permeable to gasses than other plastics, it is often favored in the food packaging industry. When used as a laminate, e.g., aluminum foil / polyester / LLDPE, it provides increased shelf life and freshness, as well as an excellent barrier against moisture and gas, notably oxygen.

Vacuum metallization, also known as thermal evaporation, is the most common PVD (Physical Vapor Deposition) process used to apply metal alloys under vacuum. Where polyester film is concerned, aluminum is vaporized inside a vacuum chamber and then bonded to a polyester sheet to achieve a uniform metalized layer. This process produces the silver-colored material often incorrectly referred to as "mylar" by consumers, while the appropriate term is "metalized polyester".

- Snack & sample portions

- Pharmaceutical applications

- ZipSeal with Tear Notch

- Wide range of applications

- Carbonated drinks

- Cold brew coffee

- Window options

- Custom Print

Interested in Learning More?

A hermetic seal on flexible packaging can be achieved with any of our sealing machines, this quick guide will help you choose the unit that will work best for your production needs.

Not every Industrial Vacuum Sealer applies to every application. There are different models and types of Vacuum Sealers available, and each one of those sealers has different features that can affect the way a production line works.

We design and manufacture custom sealing equipment to meet the unique needs of our customers. In addition to new machinery we even retrofit our customers’ existing equipment, regardless of the brand.