IMPAK Corporation’s materials are categorized by structure and thickness. MylarFoil bags are a cost-effective, efficient, and safe way to store dehydrated, freeze-dried, or lyophilized products. These products have a metalized, stretched polyester film that is flexible, light, and thin but also strong and UV-light resistant.

This packaging material has high tensile strength while also having barrier properties that isolate foods, ingredients, and supplements from the surrounding environment. With a light, flexible package, you can also remove the air inside the package and vacuum pack with these materials without concern of puncture or tearing.

We love Harvest Right freeze drying machines, and if you have one, you probably love them too. Learn more about IMPAK's selection of affordable pouches and sealers for use with your home freeze dryer.

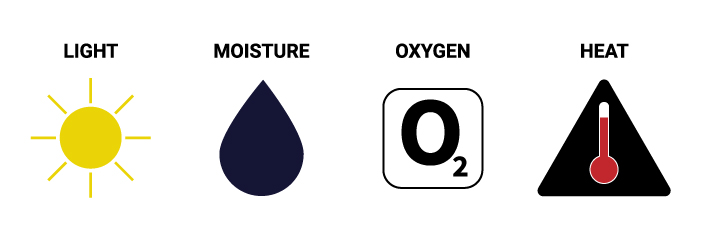

Selecting the right barrier properties for protection is important as these factors affect product quality and longevity during packing, shipping, and storage. When selecting a high-barrier packaging system for dehydrated, freeze-dried, or lyophilized products, these factors must be considered:

Removing as much oxygen, light, and moisture as possible is the best way to create long-term dried food or supplement storage success. After dehydrating your product, placing oxygen absorbers into the mylarFoil bag and sealing, ensures freshness and longevity.

When sealing foods into larger bulk food bags, the contents can be used while stored then resealed for freshness afterward without having to open and use a full package at once.

Thickness ranges from 3.5 mils up to 7mils and the thicker the bag, the more moisture and light it keeps out. Bags with high barrier properties have low oxygen transmission rate, low moisture vapor transmission rate, high tensile strength and are puncture resistant.

Our technical specialists will guide you through the following considerations:

The PAKVF4C 5.0 mil Barrier Bag allows for protection against light, oxygen and moisture featuring an inner sealing layer designed to seal directly through oils and powders that may ‘spill’ into the sealing area during fill and seal operations.

The materials for this bag meet all FDA requirements for edible product safety. For a complete review of MylarFoil Bags, visit Large Mylar® Bags for an overview of barrier bags sized over 15”, but if you need a smaller kit see our 5 Gallon Bundle option.

When high barrier packaging is paired with an oxygen absorber or desiccant, quality and longevity are greatly increased. Oxygen within packaging significantly reduces shelf life of stored ingredients, so using oxygen absorbers to remove the oxygen left in the package itself after sealing adds a great deal of protection to the contents.

Oxygen absorbers are inexpensive and rated in cubic centimeters (cc) so sizes correspond to capacity. 1ml=1cc of capacity. For a stand-alone 5-gallon bag, we recommend using a 1500 cc Oxygen Absorber for loosely packed items, and a 750 cc Oxygen Absorber for more dense, powdered products. As a 5-gallon pail liner, we recommend 750 cc for loosely packed items and 500 cc for more densely packed items.

Desiccant adsorbs moisture, reducing moisture build-up of contents. Options for desiccant that can be revitalized and reused to keep moisture at bay can be found on our Molecular Sieve page, or use our Desiccant Calculator to determine use requirements.

Need more Information? Read All About Oxygen Absorbers and if you still have questions contact one of our technical specialists for assistance and we will be happy to help.

IMPAK’s protective drum liners are manufactured from the same heavy-duty high-barrier foil laminate and have a flat, round bottom that allows for full use of the interior dimensions of the pail or drum. These large MylarFoil drum and pail liners are available in 5- and 55-gallon sizes but can be custom-produced in a variety of sizes and materials.

Following is information about multiple options suitable for dry-pack, vacuum packing, retort pouch materials and more.

The Mylar foil used in our heavy-duty drum liners is sufficient for preserving most products, however, to extend the product shelf life we recommend also using oxygen absorbers.

If you are purchasing one of our round bottom drum liners for a hygroscopic or oxygen sensitive product you may wish to consult a technical representative at the company to determine the residual air volume and how to ensure long-term efficacy of your product, especially pharmaceutical grade powders, food supplements and other products.

A sealed high-barrier bag with an oxygen absorber is what we call a “sorbent system” and is the core of IMPAK’s business.

IMPAK would typically recommend an alternative solution to oxygen absorbers for bags as with a capacity of 55 gallons, but they are not out of the question for certain applications. The alternative we would suggest would likely be a gas-purge or vacuum seal, depending on the product being packaged.

A hermetic seal on flexible packaging can be achieved with any of our sealing machines, this quick guide will help you choose the unit that will work best for your production needs.

Not every Industrial Vacuum Sealer applies to every application. There are different models and types of Vacuum Sealers available, and each one of those sealers has different features that can affect the way a production line works.

We design and manufacture custom sealing equipment to meet the unique needs of our customers. In addition to new machinery we even retrofit our customers’ existing equipment, regardless of the brand.