Child Resistant Pouches

IMPAK’s child resistant pouches come in a variety of zipper formats from sliding tab zippers to press to close zippers. All styles require two-handed dexterity to open the package. Adults have no problem opening and accessing the contents, but it is extremely difficult for children to do so. These bags are great for all sorts of products, from cleaning “pods” that resemble hard candy to pharmaceutical products.

For more information, please contact IMPAK Corporation 310-715-6600 or requests@sorbentsystems.com

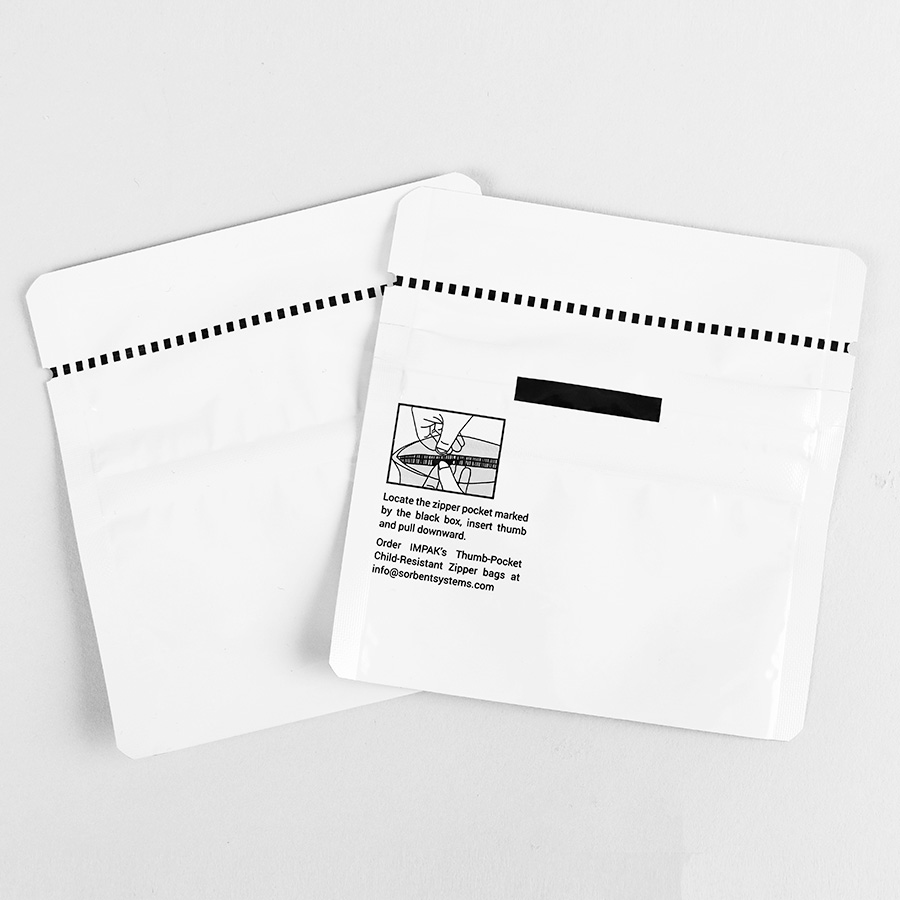

Thumb-Pocket® Child Resistant Zipseal Pouches

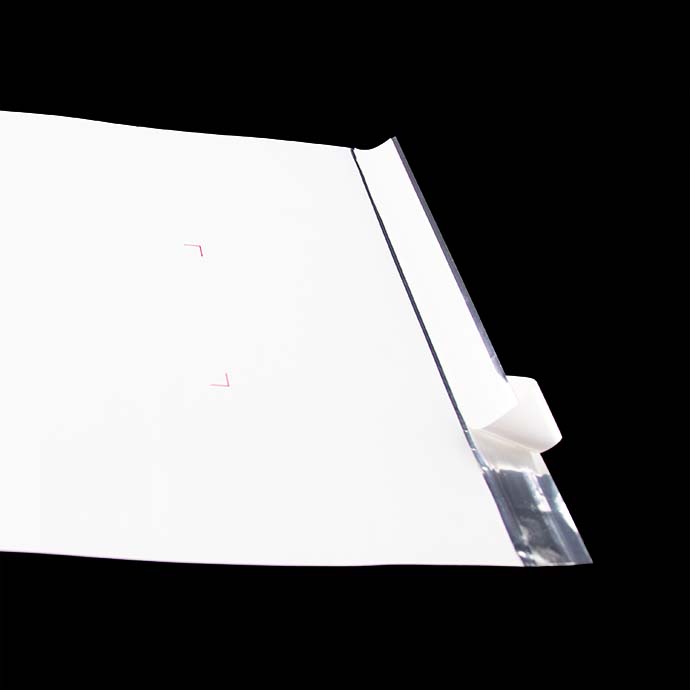

CERTIFIED, PATENTED, Child Resistant, Tamper-Evident with Perfect-Tear Technology, and a Reclosable Zipper

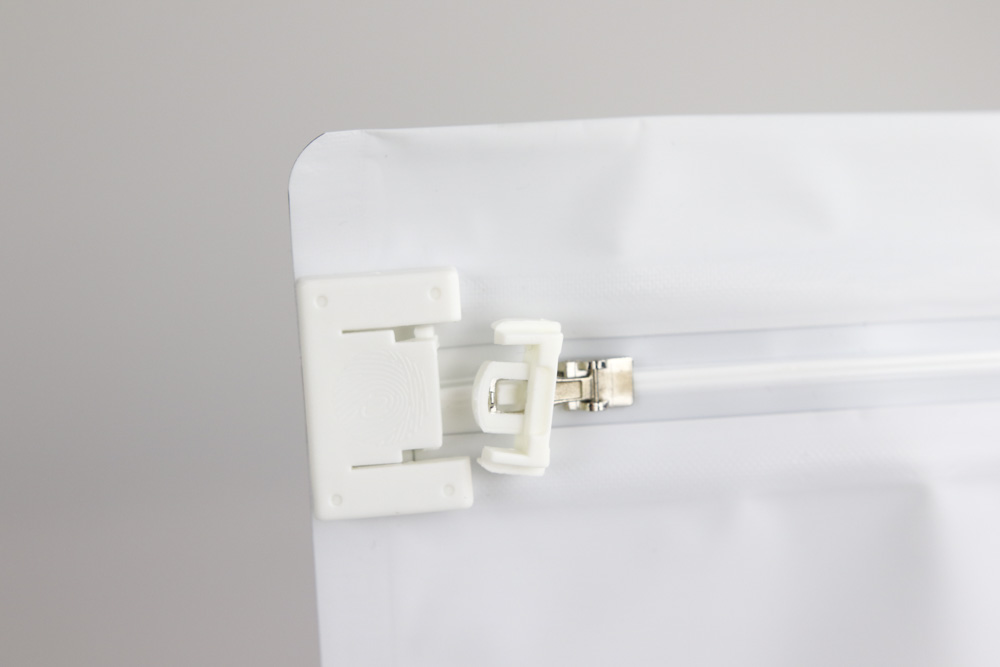

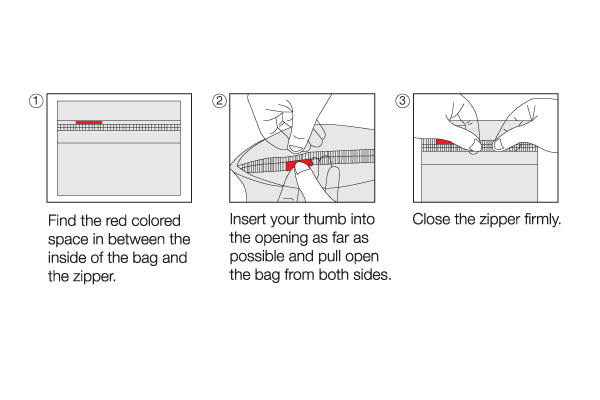

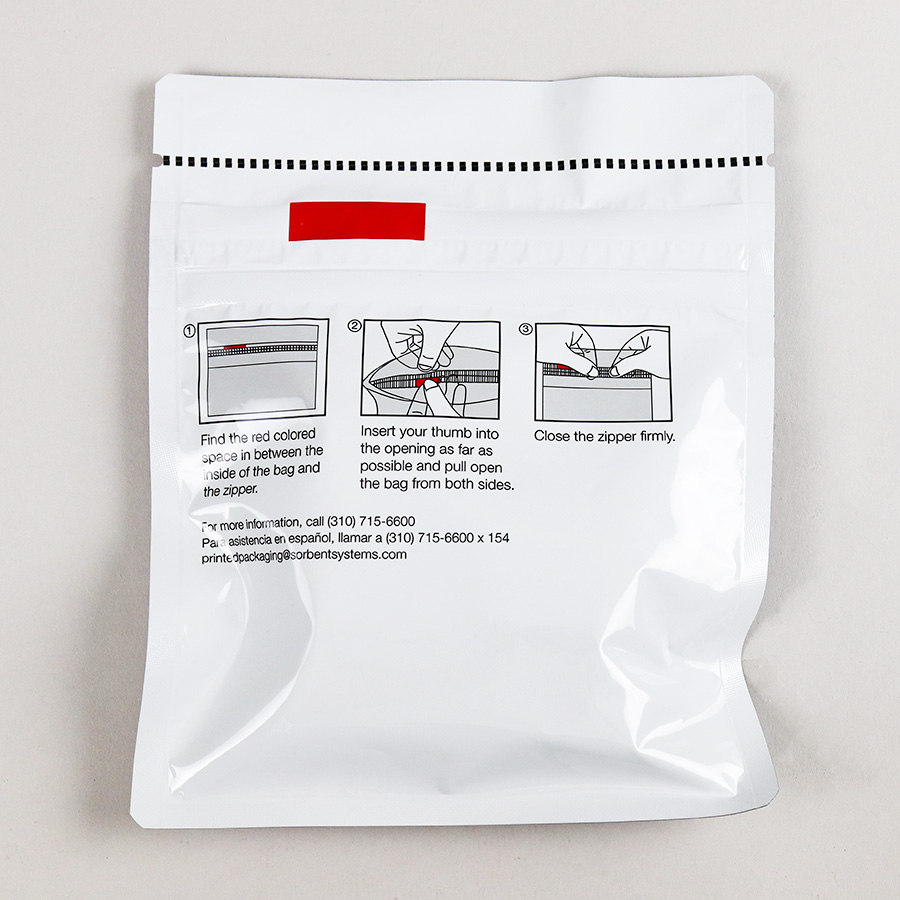

How to Open

Open following our “industry insider’s” approach: place your thumb as far as possible into the registered mark (indicated by the red box) and pull the zipper open. Try opening it from any other area and you’ll quickly see how truly remarkable the zipper is.

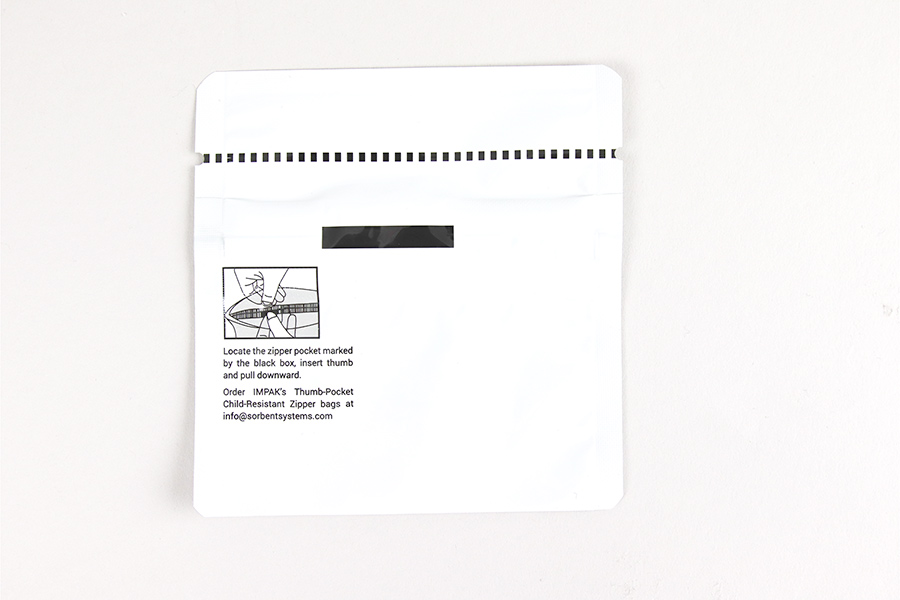

Seals in Freshness (and Scents)

Our “retail-ready” pouch is made from a food-grade, FDA-approved material that not only keeps contents dry and fresh, but also locks in scents. Bags are tamper-evident, with a tear notch that offers “perfect-tear” technology so the bag opens in a straight line to expose the reclosable child resistant zipper.

Advantages

- Less Material = Source Reduction & Cost Savings

- Better Opening Area; Easier to Reclose (as simple as a sandwich bag)

- Label Ready, Child Resistant & Tamper Evident

- Available in Small Minimum Order Quantities – starting at 100 bags

- Ideal for State Regulations: Opaque, Child Resistant, Tamper Evident

- Safe for Food: Made from FDA-Approved PAKVF3.5M Material

- Smell-Proof: Seals in Smells & Keeps Contents Fresh

- Vacuum Sealable

Shop Thumb-Pocket® Child Resistant ZipSeal Pouches

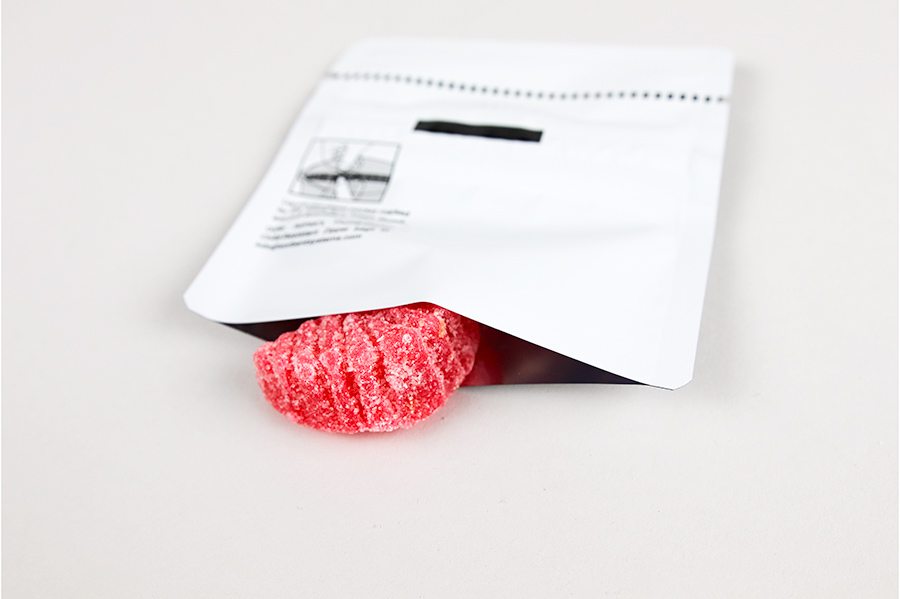

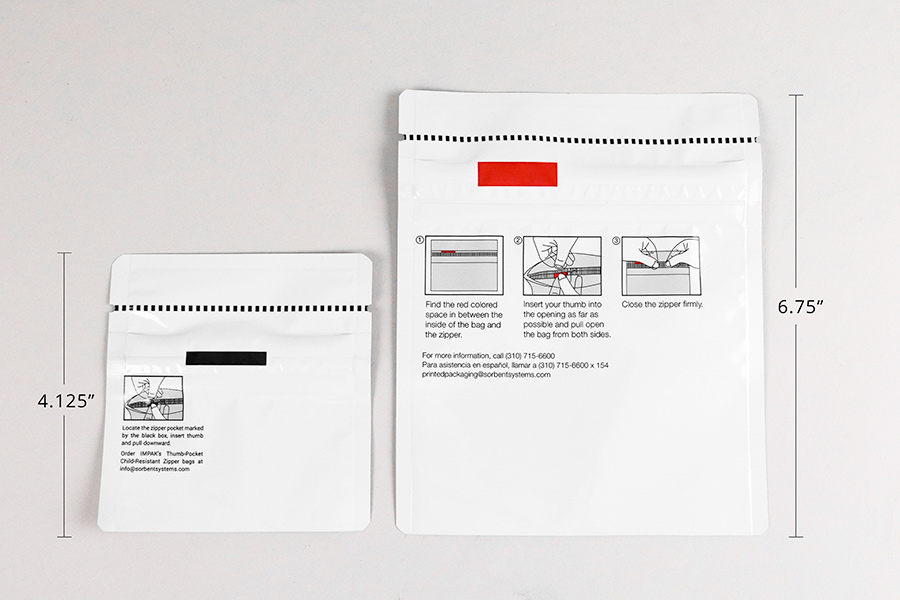

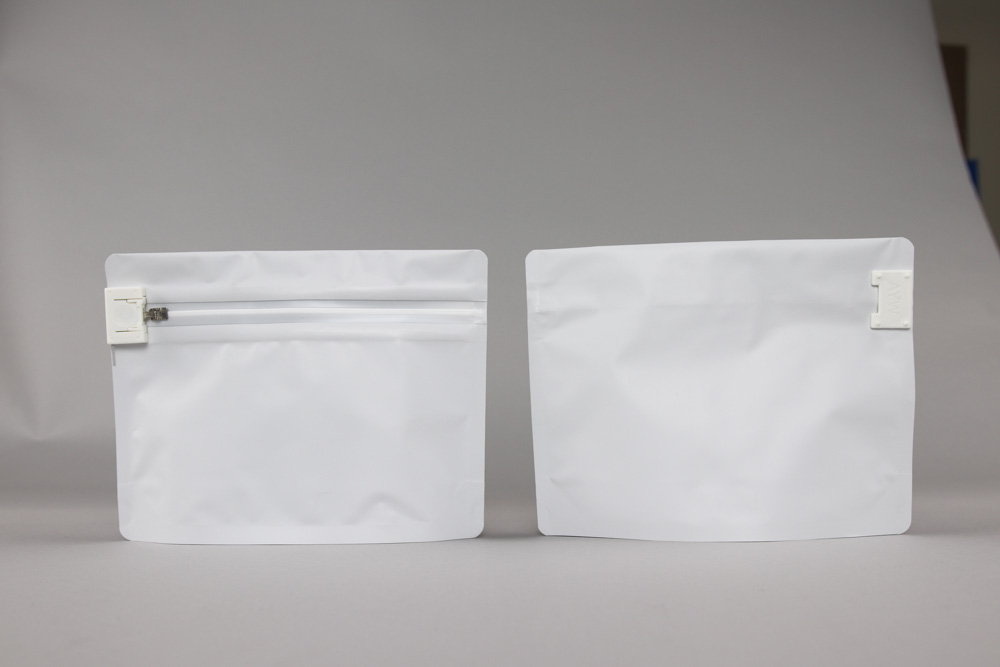

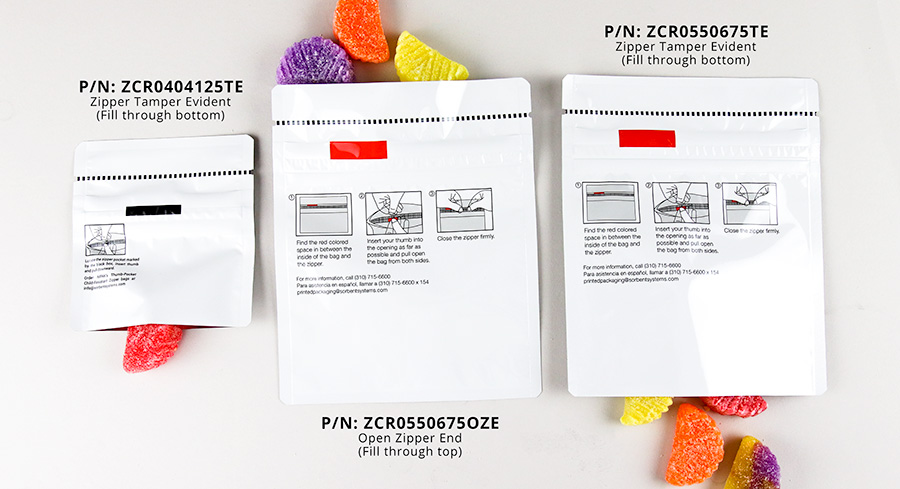

4.0" x 4.125" O.D. 1/8th Oz. CR Zipper Tamper Evident Pouch

Part Number: ZCR0404125TEMaterial: PAKVF3.5M

Case Qty: 1,000 bags/case

Fill through Bottom - REQUIRES SEALER

Trial Order

Case Pricing

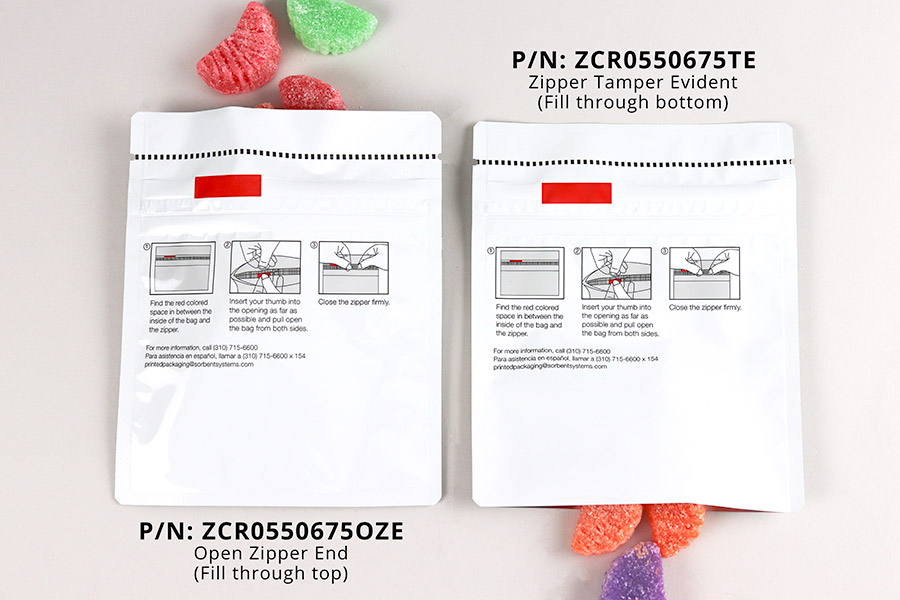

5.5" x 6.75" O.D. 1/4th Oz. CR Zipper Tamper Evident Pouch

Part Number: ZCR0550675TEMaterial: PAKVF3.5M

Case Qty: 1,000 bags/case

Fill through Bottom - REQUIRES SEALER

Trial Order

Case Pricing

5.5" x 6.75" O.D. 1/4th Oz. CR Open Zipper Pouch

Part Number: ZCR0550675OZEMaterial: PAKVF3.5M

Cast Qty: 1,000 bags/case

Fill through Top - SEALER OPTIONAL

Trial Order

Case Pricing

Single-Dose Tear Slit Bags

These small child resistant pouches are ideal for single-dose products and sample items that should be kept from children. The pouches are sealed on 3 sides, with an end left open to be filled and followed with a heat seal. The multi-layer material provides a strong barrier against moisture, oxygen, light and smell. In addition to excellent barrier properties, the pouch’s inside layer is an FDA-Approved food-grade material. Following the heat seal, the pouches are both tamper-evident and child resistant.

How to Open:

To open, users fold the corner edge over and tear along a pre-cut slit on the bag as indicated on the printed instructions on the pouch. The small tear slit is surrounded by a seal on all sides which means it does not reach the outer edge of the bag, nor does it reach the inner edge of the bag so air and moisture cannot get in.

Add branding with adhesive labels or a custom print order.

Shop Single-Dose Child Resistant Pouches

3.0" x 4.5" O.D. Silver Child Resistant Single-Dose Pouch with Tear Slit and dashed line print

Part Number: CR03045TSMaterial: PAKVF4

Case Qty: 5,000 bags/case

Fill through Bottom - REQUIRES SEALER

Trial Order

Case Pricing

3.5" x 3.5" O.D. White Child Resistant Single-Dose Pouch with Tear Slit

Part Number: CRW03250325TSMaterial: PAKVF4W

Case Qty: 5,000 bags/case

Fill through Bottom - REQUIRES SEALER

Trial Order

Case Pricing

3.5" x 3.5" O.D. Silver Child Resistant Single-Dose Pouch with Tear Slit

Part Number: CR03250325TSMaterial: PAKVF4

Case Qty: 5,000 bags/case

Fill through Bottom - REQUIRES SEALER

Trial Order

Case Pricing

9.0" x 13.0" x 1.0" - Custom Brown Kraft Bag

O.D Lip and Tape

3 Side Seal Pouch

Child Resistant Tear Slit

Lip and Tape

Part Number: MTC5BK0913TSCase Qty: 1,000 bags/case

Case Pricing

9.0" x 13.0" x 1.0" - Custom Printed

O.D Lip and Tape

3 Side Seal Pouch

Child Resistant Tear Slit

Lip and Tape

Part Number: MTC25MW0913TSCase Qty: 1,000 bags/case

Case Pricing

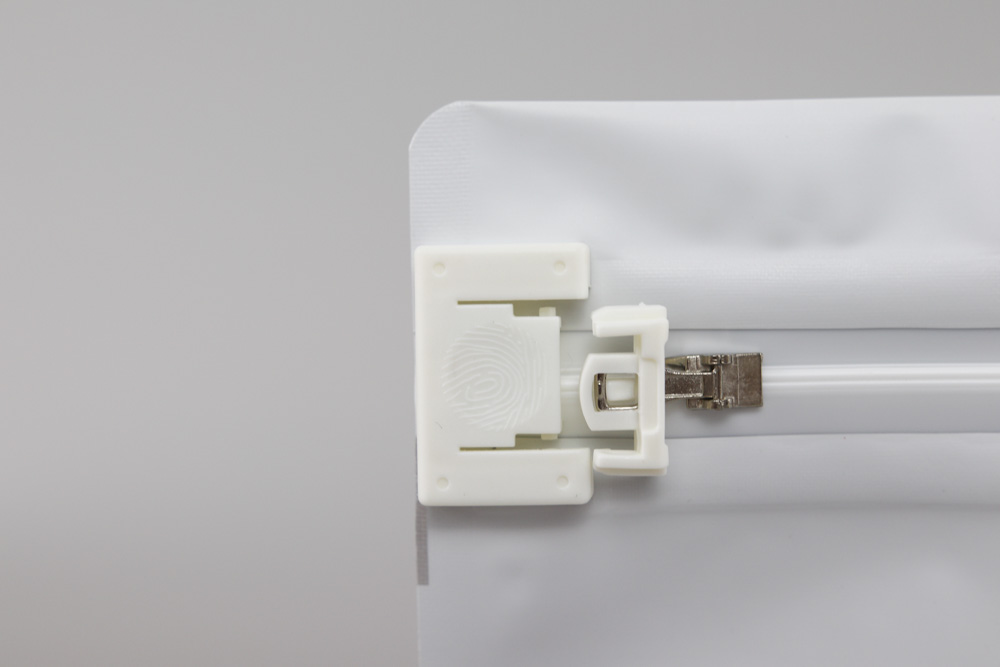

PharmaLoc™ Child Resistant Zipper Bags

IMPAK’s modified pouch comes installed with a special tab requiring two handed dexterity to open the package. It’s easy for adults to open and access the contents, but extremely difficult for children to do so. These bags are great for all sorts of products, from cleaning “pods” that resemble hard candy to medical marijuana.

Our child-resistant pouches are designed to meet ASTM (American Society for Testing and Material) D3475 (Child Resistant) standards.

How to Open:

PharmaLoc™ Zipper Bags come with two different lock styles, depending on the color bag you select. See details below.

How to Open Black Pin-Latch Style:

Lift latch up to "unlock" bag, with latch lifted, pull the slider zipper out and slide open.

How to To Open White Press-to-Unlock Style:

Press central button down and while pressed down, pull the slider zipper out and slide open.

Add branding with adhesive labels or a custom print order.

Shop PharmaLoc™ Child Resistant Zipper Pouches

8.0" x 6.0" x 2.36" O.D. Black PharmaLoc™ stand up pouch with child resistant ZipSeal

Part Number: ZCR0806BG3Material: Contact for Material Specifications

Case Qty: 250 bags/case

Fill Past Zipper - No Sealer Needed

Trial Order

Case Pricing

8.0" x 6.0" x 2.36" O.D. White PharmaLoc™ stand up pouch with child resistant ZipSeal

Part Number: ZCR0806WG3Material: Contact for Material Specifications

Case Qty: 250 bags/case

Fill Past Zipper - No Sealer Needed

Trial Order

Case Pricing

12.5" x 9.0" x 4.0" O.D. Black Child Resistant Exit Bag

Part Number: ZCR122509BG3Material: Contact for Material Specifications

Case Qty: 250 bags/case

Fill Past Zipper - No Sealer Needed

Trial Order

Case Pricing

12.5" x 9.0" x 4.0" O.D. White Child Resistant Exit Bag

Part Number: ZCR122509WG3Material: Contact for Material Specifications

Case Qty: 250 bags/case

Fill Past Zipper - No Sealer Needed

Trial Order

Case Pricing

Child-Guard® Push-Pin Zipper Bags

The proven industry standard, used by Tide® for detergent pods. The sliding zipper has a pin that must be inserted to “unlock” contents. This simple but effective zipper can be applied to a wide range of sizes to serve many markets.

See the PDF Guide: Child-Guard® Child-Resistant Zipper

How to Open:

- Slide tab to left side

- Align slider pin with notch in zipper

- Press pin down and pull slider back

- Slide back to reclose

Add branding with adhesive labels or a custom print order.

Interested in Learning More?

IMPAK produces custom printed pouches and packaging with an emphasis on materials with distinctive barrier properties to protect products from the adverse effects of moisture, oxygen, light and more. Learn about our unique custom capabilities.

High barrier bags are used to preserve and protect products. When paired with an oxygen absorber or desiccant, products enjoy even greater shelf-life and stability. However, selecting the appropriate package is not always as straight forward as it seems.

Not every Industrial Vacuum Sealer applies to every application. There are different models and types of Vacuum Sealers available, and each one of those sealers has different features that can affect the way a production line works.