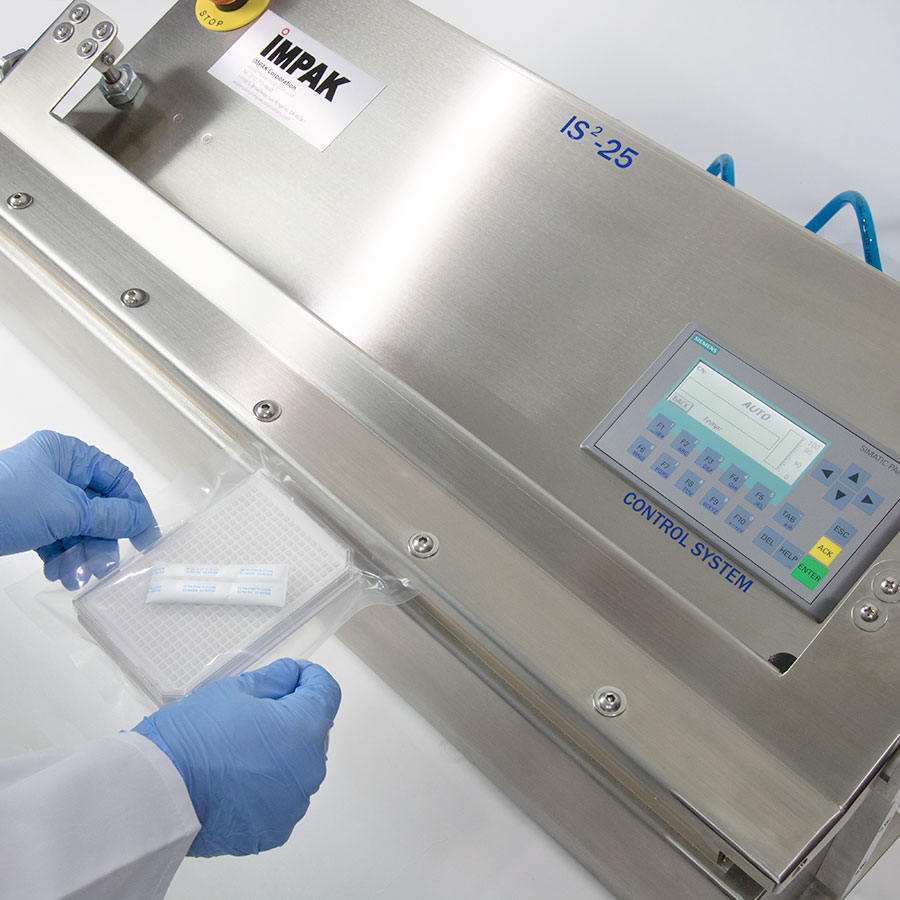

The iS2 (Intelligent Sealing System) is a control system for heat sealing equipment that offers pin-point digital control over time, temperature, and pressure, via touch screen interface.

The system is more than a digital control upgrade, it combines an advanced Siemens PLC and HMI with proprietary pneumatic and electrical components, to deliver temperature control within one degree, accurate sealing time with readings every millisecond. Additional conveniences such as recipe storage, operator locks, and graphs of time/temperature put iS2 enabled sealers in a class of their own.

The iS2 is customizable; IMPAK’s machinery specialists evaluate the needs of each customer to create a list of software features and components specific to their individual project.

*Impak is capable of retrofitting this system on the equipment it builds, as well as, competitor's equipment for a thermal impulse heat, vacuum sealers, or constant heat sealing systems

IMPAK currently uses 3 different Siemens HMIs with the iS2 System. The HMI used is determined by the size of machine; table top machines utilize the smaller touchpad HMI, whereas large frame machines utilize the touchscreen HMI. Read more about the benefits of the iS2 below.

"IMPAK’s iS2(Intelligent Sealing System) is a platform that utilizes an advanced Siemens PLC, Siemens HMI, and proprietary pneumatic and electrical components to produce heat/vacuum seal solutions. The ports and features it provides that make the calibration easy and efficient. Over the years, IMPAK has invested resources in developing features and technologies to advance its heat and vacuum sealers."

- Johnathan Brown, PME Services, Inc.

Advanced Siemens HMIs with Settings, Auto and Manual Test Menus. Touchpad or Touchscreen operation.

For legal reasons we claim “±3” degree temperature accuracy, but most tests show accuracy of ±1 degrees F. The system takes temperature readings every 1-2ms.

Pressure control with 0.1PSI consistency and high tech proportional valve. Control high and low pressure from the HMI.

Adjust seal time in 1/10 second increments directly from the HMI.

Set independent thermocouple temperatures directly from the HMI.

A recipe is defined as the precise formula for temperature, pressure, and sealing parameters required for a specific material and application. Some companies in the industry refer to this formula as a recipe. We're uncomfortable with the term recipe used in this application since it implies vagueness, e.g., terms similar to 'pinch of salt' and a 'dash of vinegar' would not be acceptable. Since it is our nature to be specific and accurate for delivering technical solutions at IMPAK Corp, we refer to them as formulas. Wouldn't you rather be able to set your seal heat temperature at 243.7 deg F (117.61 C?)

| Touchpad | Touchscreen | Advanced Touchscreen | |

|---|---|---|---|

| CPU | CPU 212 | CPU 215 | CPU 215 |

| Number of Recipes | 5 | 100 | 500 |

| USB Port | 0 | 1 | 2 |

| Pneumetic Proportional Valve | check | check | check |

| Temperature Control Module | check | check | check |

| Temperature Accuracy within ±3° F | check | check | check |

| Vacuum Sensor | check | check | |

| Trend of Graph | check |

Challenge: IMPAK was contacted by a large firm that manufactures plastic films with a challenge; upgrade a hand held heat sealer with old technology TIC (temperature impulse controller) and timer so that precise heat and cool temps can be measured and monitored. The heat sealer is used in their QC Lab and research and design lab to construct and test prototypes.

Background: The customer had a hand held heat sealer that was produced by Aline Corporation (www.alinesys.com) that was no longer functioning. Although Aline went bankrupt in 2012, IMPAK Corporation’s Machinery Group is committed to supporting and manufacturing all of the sealing units that were previously produced by Aline. They were hoping to repair the sealer quickly and economically.[see full article]

Almost any sealing equipment can be converted to the iS2 system, from tabletop units to large free-standing units, and even chamber vacuum sealers and tube sealers. Although most companies select new equipment manufactured by IMPAK, the company has integrated the iS2 system into equipment made by other manufacturers.

IMPAK has produced sealing equipment with the iS2 System on the following formats:

Learn more about the iS2-compatible units below.

Tabletop units represent a large percentage of the demand for validatable sealing equipment. Pharmaceutical and medical device producers require the repeatable results offered by the system for validation purposes. For this reason, IMPAK offers readily-available tabletop equipment with the iS2 pre-installed and priced in. These units are available with 15”, 20” and 25” seal lengths. Stock units are seal-only, but vacuum units are available by order. Contact our team for custom units, and see our stock units here: iS2 Tabletop Sealer.

Watch Videos:

iS2 Validatable Medical Pouch Sealer with Safety-Shield Option

Validatable Vacuum Sealer - IMPAK iS2 Platform

Select Gramatech sealers may be upgraded to the iS2 system, including the tabletop Workhorse, as well as the freestanding Custom Pak. These represent some of IMPAK's most robust, production-oriented units, and they are only made better with the iS2 system. Contact our team for custom units, and see our stock units here: WorkHorse and Custom Pak.

Watch Videos:

WorkHorse with iS2 Upgrade

iS2 chamber sealers offer a higher degree of control, as well as more convenient touchscreen interface, plus the option to store multiple recipes. The iS2 system does not come pre-installed on chamber vacuum sealers; this is an upgrade and begins with a call to our machinery specialists so they can assess your needs and offer a custom system. Generally, we suggest the iS2 system for 520 units and up and do not offer on smaller units unless by unique requirement. The upgrade pricing to the iS2 System will depend on your specific needs. Speak to a specialist today, and see the base-model chamber sealers, without iS2 upgrade here: Stock Chamber Sealers.

Watch Videos:

IMPAK iS2 Medically Validatable Chamber Sealer

iS2 Medically Validatable Chamber Vacuum Sealer from IMPAK

This category of large sealing equipment is often referred to as “LFIG” for “Large Frame Industrial Grade.” IMPAK defines “large frame” as free-standing units, with seal lengths of 36” and up. These units are offered in horizontal and vertical configurations and are custom built with available features such as vacuum and gas-flush options. LFIGs are built in the USA at IMPAK’s California facility, and as such, the iS2 System is installed standard on every unit. IMPAK’s machinery specialists will closely examine your challenge to deliver a sealing system to suit your needs. Options include 3rd-Party Certification, Explosion-Proof Builds, and much more. Learn more here: LFIG Sealers

Watch Video:

Horizontal Large Frame Sealer with Cut Wire (LFIG)

IMPAK offers a 30” pneumatic multi-tube sealer, item MSTSS760 (formerly TP-30), which can be upgraded to the iS2 system. The standard MSTSS760 has analog controls, whereas the upgraded unit features digital control and temperature accuracy within 2 degrees. Like all upgrades to the iS2, this is not simply a controller upgrade, it involves a range of enhanced components. See videos of the iS2 Pneumatic Tube Sealer below, and visit the base unit page here: MSTSS760 - Pneumatic 30" Tube Sealer

Watch Video:

IMPAK iS2 - Validatable Tube Sealer

A hermetic seal on flexible packaging can be achieved with any of our sealing machines, this quick guide will help you choose the unit that will work best for your production needs.

Not every Industrial Vacuum Sealer applies to every application. There are different models and types of Vacuum Sealers available, and each one of those sealers has different features that can affect the way a production line works.

We design and manufacture custom sealing equipment to meet the unique needs of our customers. In addition to new machinery we even retrofit our customers’ existing equipment, regardless of the brand.